Turbodisc 25 Rotating Nozzle

Plain bearing nozzle with fast rotation

and particularly resistant

- no ball bearings

- fast rotation and small amounts of liquid

- FDA compliant & EX certified

- very temperature resistant

- only a few individual components

- also available in plastic

- high operational safety, absolutely hygienic

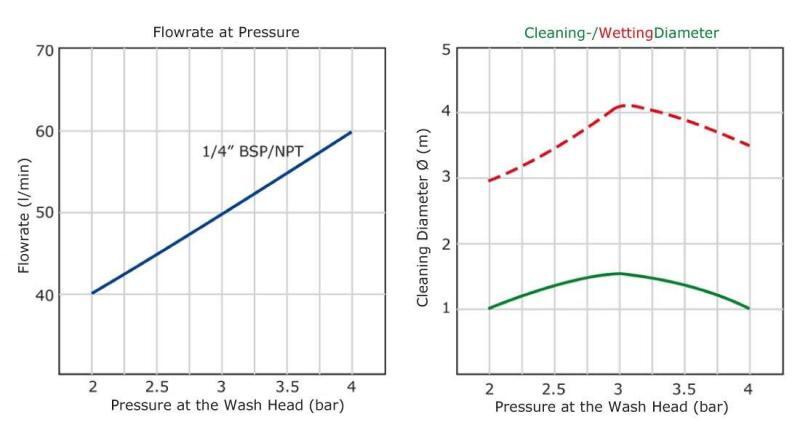

| Technical Data | Value |

|---|---|

| Max. cleaning diameter: | 1,5 Meter |

| Spray pattern: | 360° and 180° up-, downwards |

| Pressure range: | 2 – 4 bar |

| Flow rate: | 40 – 60 LPM (2,4 – 3,6 m³/h) |

| Insertion opening: | min. Ø 31 mm |

| Mounting position: | arbitrary |

| Weight: | ca. 0,05 KG |

| Materials: | Stainless Steel 316L (1.4404), C.PTFE, PTFE, C.PEEK, PEEK |

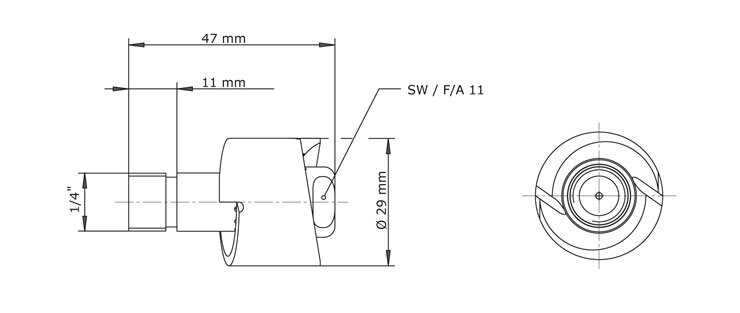

| Pipe connection: | 1/4″ External Thread BSP (NPT) |

| Alternative connection: | 1/2″ Split pin, DN10 Split pin |

| Nozzle characteristics: | Rotating Rotordisc |

| Certificates: | 3.1, 2.2, ATEX, FDA Regulation (EC) No 1935/2004 |

| Max. operating temperature: | 95°C (203°F) |

| Max. ambient temperature: | 140°C (284°F), 30 Min. |

| Operating recommendation: | It is recommended to install a filter/strainer (500 μm) in the CIP supply line to the tank cleaner to protect it from particle clogging or damage. |

Fast-rotating Turbodiscs create a permanently even, drop-shaped liquid distribution. Thanks to the intelligent liquid storage, these rotating nozzles are extremely durable compared to their ball-bearing counterparts. Turbodisc have already achieved operating times of over 25 years. Some of these products are highly resistant to high temperatures or service with steam or compressed air. An extensive range of 180° spray patterns is available with many connection options and materials. Turbodisc are ideal for installation in conveyor and filling systems as well as for cleaning sterile tanks.

The TURBODISC is a fast rotating tank cleaner that is perfect for replacing static spray balls. By that replacement, the consumption of liquid or the time required for cleaning can often be significantly reduced. During operation, the cleaning medium drives the rotor, which rotates friction-free and at high speed on a bearing made of cleaning fluid. This procedure turns the fluid into many high-energy drops, which are thrown against all areas around the cleaning nozzle at the same time and at high speed. As a consequence a spherical spray pattern is created around the nozzle, that can effectively clean the walls of the tank.

With the Turbodisc, the time and liquid required for cleaning a vessel can often be extremely reduced. The Turbodisc 25-360AF can be operated in any position; in vertical operation, optimum residual emptying is ensured. The Turbodisc 25-360 is very heat resistant and can be used at ambient temperatures of up to 250°C under certain circumstances. All TURBODISC Nozzles also promise exceptionally long service life when used with compressed air or in superheated steam sterilization and high temperatures.

For use in ATEX and FDA applications, all certificates are available for the Turbodisc 25-360AF at the same time for the first time. This enables the use of this product in almost all application areas. Areas of application: Brewery, beverage, dairy processing, food, pharmaceutical, chemical and transport industries. Rinsing, cleaning and wetting of vessels, tanks or plant components of various dimensions, process vessels, reactors, dryers, granulators, storage tanks, coating machines and tank containers.

Turbodisc 25 Variants

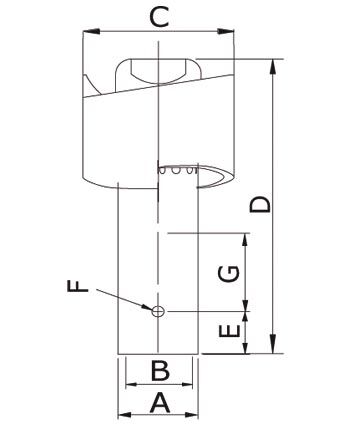

TD25 Measurements and Connection Types

| TD25 Abmessungen und Anschlusstypen | |||||||

|---|---|---|---|---|---|---|---|

| B* (split pin version) corresponds to the inner diameter of the Turbodisc for mounting on a pipe whose max. outer diameter must be taken into account. Further special adaptations possible. When purchasing a split pin version, the exact outside diameter of the existing pipe must be known. A suitable split pin is supplied. BSP thread types are also available as NPT thread version. Split pin mounting up to 15% higher flow. | |||||||

| Dimensions (mm) | A | B* | C | D | E | F | G |

| TD25 1/4″ AG-BSP | 16,50 | 1/4″ AG-BSP | 29,00 | 47,00 | – | – | – |

| TD25 1/2″ Split pin | 16,50 | 12,75 – 12,80 | 29,00 | 47,00 | 10,00 | 2,50 | – |

| TD25 DN10 Split pin | 16,50 | 13,08 – 13,10 | 29,00 | 47,00 | 10,00 | 2,50 | – |

Turbodisc 25 Threaded Connection

| Connection | Spraypattern | Pipe* | Product Code | Materials | Certificates | Article number |

|---|---|---|---|---|---|---|

| *corresponds to the max. pipe outside diameter of the pipe on which the nozzle is to be installed (inch or mm). Recommended standard units with high stock probability are shown in blue. All Turbodiscs are available with electric and hand polishing. Code example: TD25AFP-360-BSP – polish < RA 0.8. Turbodisc are available with PEEK bearing (FDA only, no ATEX). Code example: TD25F-PEEK-360-BSP. Turbodisc are available with C.PEEK bearing (ATEX + FDA). Code example: TD25AF-CPEEK-360-BSP. Further adaptations of the connection dimensions are possible. 180T=towards/upwards, 180A=away/downwards. Turbodisc rotary nozzles can be manufactured from Hastelloy C22. | ||||||

| 1/4″ AG-BSP | 360° | 1/4″ | D25AF-360-BSP | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-1678-113 |

| 1/4″ AG-BSP | 360° | 1/4″ | D25AF-360-BSP | 316L/PTFE | FDA, 3.1 | 4660-1603-002 |

| 1/4″ AG-BSP | 180° downwards | 1/4″ | TD25AF-180A-BSP | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-1664-113 |

| 1/4″ AG-BSP | 180° downwards | 1/4″ | TD25F-180A-BSP | 316L/PTFE | FDA, 3.1 | 4660-1665-012 |

| 1/4″ AG-BSP | 180° upwards | 1/4″ | TD25AF-180T-BSP | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 1/4″ AG-BSP | 180° upwards | 1/4″ | TD25F-180T-BSP | 316L/PTFE | FDA, 3.1 | – |

| 1/4″ AG-NPT | 360° | 1/4″ | TD25AF-360-NPT | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-1677-203 |

| 1/4″ AG-NPT | 360° | 1/4″ | TD25F-360-NPT | 316L/PTFE | FDA, 3.1 | 4660-1604-202 |

| 1/4″ AG-NPT | 180° downwards | 1/4″ | TD25AF-180A-NPT | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 1/4″ AG-NPT | 180° downwards | 1/4″ | TD25F-180A-NPT | 316L/PTFE | FDA, 3.1 | – |

| 1/4″ AG-NPT | 180° upwards | 1/4″ | TD25AF-180T-NPT | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 1/4″ AG-NPT | 180° upwards | 1/4″ | TD25F-180T-NPT | 316L/PTFE | FDA, 3.1 | – |

Turbodisc 25 Split pin Connection

| Connection | Spraypattern | Pipe* | Product Code | Materials | Certificate | Article Number |

|---|---|---|---|---|---|---|

| *corresponds to the max. pipe outside diameter of the pipe on which the nozzle is to be installed (inch or mm). Recommended standard units with high stock probability are shown in blue. All Turbodiscs are available with electric and hand polishing. Code example: TD25AFP-360-BSP – polish < RA 0.8. Turbodisc are available with PEEK bearing (FDA only, no ATEX). Code example: TD25F-PEEK-360-BSP. Turbodisc are available with C.PEEK bearing (ATEX + FDA). Code example: TD25AF-CPEEK-360-BSP. Further adaptations of the connection dimensions are possible. 180T=towards/upwards, 180A=away/downwards. Turbodisc rotary nozzles can be manufactured from Hastelloy C22. | ||||||

| 1/2″ Split pin | 360° | 12,70 | TD25AF-360-PF | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-1685-413 |

| 1/2″ Split pin | 360° | 12,70 | TD25F-360-PF | 316L/PTFE | FDA, 3.1 | 4660-1674-412 |

| 1/2″ Split pin | 180° downwards | 12,70 | TD25AF-180A-PF | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 1/2″ Split pin | 180° downwards | 12,70 | TD25F-180A-PF | 316L/PTFE | FDA, 3.1 | – |

| 1/2″ Split pin | 180° upwards | 12,70 | TD25AF-180T-PF | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 1/2″ Split pin | 180° upwards | 12,70 | TD25F-180T-PF | 316L/PTFE | FDA, 3.1 | – |

| DN10 Split pin | 360° | 13,00 | TD25AF-360-DN10 | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| DN10 Split pin | 360° | 13,00 | TD25F-360-DN10 | 316L/PTFE | FDA, 3.1 | – |

| DN10 Split pin | 180° downwards | 13,00 | TD25AF-180A-DN10 | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| DN10 Split pin | 180° downwards | 13,00 | TD25F-180A-DN10 | 316L/PTFE | FDA, 3.1 | – |

| DN10 Split pin | 180° upwards | 13,00 | TD25AF-180T-DN10 | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| DN10 Split pin | 180° upwards | 13,00 | TD25F-180T-DN10 | 316L/PTFE | FDA, 3.1 | – |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All data are without guarantee. (Stand: 29.11.2022-71427321893-1888948-71042)