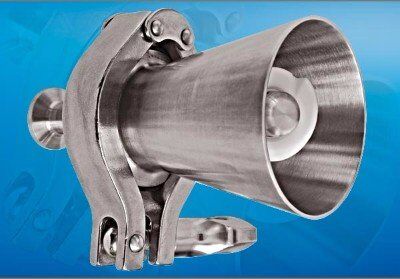

Turbo CW 25/75 Target cleaner

Target cleaning of an area,

hygienic & self-cleaning

- no ball bearings

- hygienic & self-cleaning

- horizontal & vertical

- maintenance-free operation possible

- very few single components

- optimal for shaded areas

- continuous spray strength

| Technical Data | Value |

|---|---|

| Spray characteristics: | CW25 1 m horizontal with 200 mm Ø round spray pattern, CW75 1 m horizontal with 1 m Ø round spray pattern |

| Spray pattern: | Target oriented |

| Pressure range: | CW25 2 – 6 bar, CW75 4 – 8 bar |

| Flow rate: | CW25 40 – 70 LPM (2,4 – 4,2 m³/h), CW75 105 – 150 LPM (6,3 – 9,0 m³/h) |

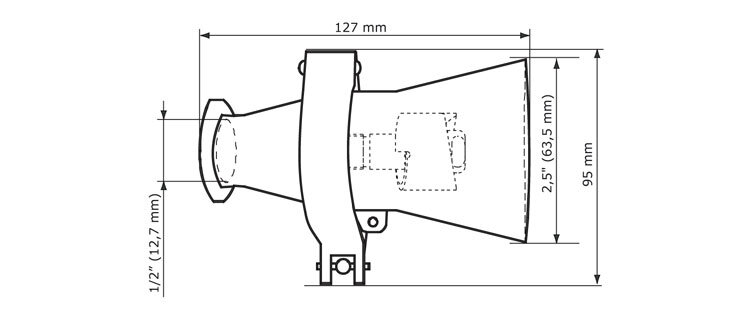

| Insertion opening: | CW25 min. Ø 100 mm, CW75 min. Ø 110 mm |

| Mounting position: | arbitrary |

| Weight: | on request |

| Materials: | Stainless Steel 316 (1.4401), 316L (1.4404), C.PTFE, PTFE, EPDM |

| Standard Pipe connection: | KCW25 1/2” Clamp connection, 2,5” Welded connection, CW75 1” Clamp connection, 3” Welded connection |

| Optional Pipe connections: | on request |

| Nozzle characteristics: | CW25 Turbodisc 25 360°, CW75 Turbodisc 75 360° |

| Certificates: | 3.1, 2.2, ATEX, FDA, FDA Regulation (EC) No 1935/2004 |

| Max. operating temperature: | 95°C (2003°F) |

| Max. ambient temperature: | 140°C (284°F), 30 Min. |

| Operation recommendation: | It is recommended to install a filter/screen (500 μm) in the CIP inlet line to the tank cleaner to protect it from clogging with particles or damage. |

Turbo CW 25

| Pressure bar | Flowrate LPM (m³/h) | Spray radius diameter in meters |

|---|---|---|

| 2 | 40 (2,4) | Depending on the distance to the target area and pressure the Turbo CW25 creates a spray radius of 2 – 6 meters |

| 3 | 50 (3,0) | |

| 4 | 60 (3,6) | |

| 5 | 65 (3,9) | |

| 6 | 70 (4,2) |

Turbo CW 75

| Pressure bar | Flowrate LPM (m³/h) | Spray radius diameter in meters Distance to target in meters | |||

|---|---|---|---|---|---|

| 1 m | 2 m | 3 m | 4 m | ||

| 4 | 105 (6,3) | 1,0 | 1,2 | – | – |

| 5 | 120 (7,2) | 1,0 | 1,5 | – | – |

| 6 | 130 (7,8) | 1,0 | 1,5 | 1,5 | – |

| 7 | 140 (8,4) | 1,2 | 1,5 | 1,8 | – |

| 8 | 150 (9,0) | 1,2 | 1,5 | 1,8 | 2,0 |

The TURBO CW25/75 is specially designed for targeted cleaning of hard-to-reach areas. Inside a hopper, a Turbodisc 25/75 creates a forward-emerging spray pattern with high-energy droplets. The cleaning nozzle constantly cleans itself during operation.

The TURBO CW25/75 can be mounted in the vessel on a pipe feeder, or welded directly to the vessel wall. The Turbodisc 25/75 can be easily removed from the hopper at any time, the unit works in any installation position and is very insensitive to contamination. A vertical downward position allows the TURBO CW25/75 to specifically clean conveyors or their sections.

The targeted water jet enables cleaning of agitator parts in horizontal and vertical operation, and can also be welded directly to the tank wall in the correct position without colliding with the agitator. The TURBO CW25/75 can be used for cleaning pipe areas. Likewise, the cleaning of shadow areas in tanks is possible by installing it in a sensible position. The TURBO CW25/75 is a cost effective replacement solution for retractable cleaning nozzles.

Areas of application: Brewing, beverage, dairy processing, food, pharmaceutical, chemical and transportation industries. Flushing or cleaning of problem areas, shadow areas, agitators, struts, corner areas in containers or in conveyor and transport systems.

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 22.12.2022-71427321893-1888948-71042)