Troll Ball 2″ Rotating Nozzle

Plain bearing, jetforming, slowly rotating rotating nozzle with strong cleaning effect

- low pressure plain bearing 360° rotating nozzle

- slow radiation with low consumption values

- FDA compliant & EX certified

- acid, alkali and temperature resistant

- compact dimensions

- self-cleaning, hygienic, low-wear

- high operational reliability

| Technical Data | Value |

|---|---|

| Max. cleaning diameter: | 4,5 meters |

| Spray pattern: | 360° and 180° up-, downwards |

| Pressure range: | 3 – 12 bar |

| Flow rate: | 50 – 100 LPM (3,0 – 6,0 m³/h) |

| Insertion opening: | min. Ø 60 mm |

| Mounting position: | arbitrary, preferrably vertical downwards |

| Weight: | approx. 1,1 KG |

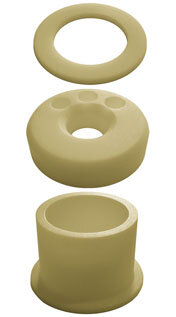

| Materials: | Stainless Steel 316L (1.4404), 316 (1.4401), C.PTFE, PTFE, (PEEK) |

| Pipe connection: | 3/8″ Internal Thread BSP, BSPT (NPT) |

| Optional Pipe Connections: | 1/2″ Splint |

| Nozzle characteristics: | Ball with slots |

| Certificates: | 3.1, 2.2, ATEX, FDA Regulation (EC) No 1935/2004 |

| Max. operating temperature: | 95°C (203°F) |

| Max. ambient temperature: | 140°C (284°F), 30 Min. |

| Operating recommendation: | It is recommended to install a filter/strainer (500 μm) in the CIP supply line to the tank cleaner to protect it from particle clogging or damage. |

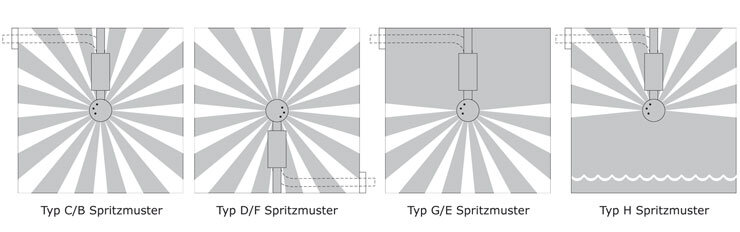

Cleaning focus 360°, main effective area horizontal and upwards, developed for standard cleaning applications,

Alternative: FanJet Type B.

Cleaning focus 360°, main effective area horizontal and upwards, designed for installation upside down with effective area upwards,

Alternative: FanJet Type F.

Cleaning focus 180°, main area of action horizontal and downwards, developed for installation in open container types,

Alternative: FanJet Type E.

Cleaning focus 180°, main area of action horizontal and upwards, developed for ceiling cleaning.

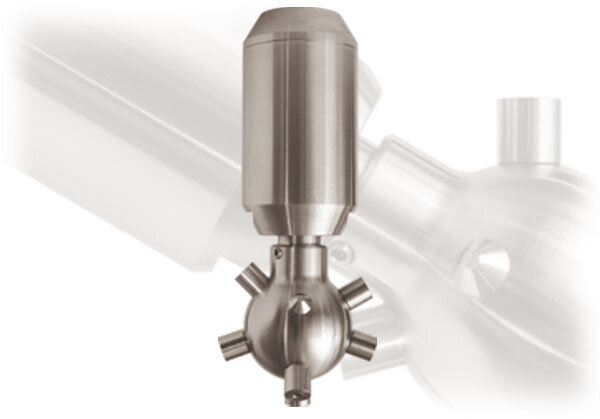

The Troll Ball is a rotating cleaning nozzle whose ball head is equipped with drillholes instead of slots. The ball-bearing-free and wear-resistant drive system generates a slow rotation in which strong, bundled liquid jets with high impact force are formed. The individual jets cover each other, which means that a complete 360° cleaning action is achieved. Troll Balls are also available in 180° variants and with attached flat jet or bundle nozzles to improve coverage or increase the jet strength. Troll Ball rotating nozzles are robust and almost indestructible and can be easily serviced or repaired in the event of a defect. Every component of a Troll Ball is available as a spare part.

The simple and effective drive system of the TROLL BALL 2″ creates a slow and constant rotation.

This process provides continuous cleaning with different cleaning media and a wide temperature range. The TROLL BALL has few moving parts, providing a compact, reliable, and low-maintenance cleaning solution. The TROLL BALL is ideal as a replacement for fixed or rotating spray balls.

The cleaning fluid drives a simple motor that produces constant rotation of the ball head. The entire cleaning liquid flows with effective force through the few holes in the spray ball. The specially developed design of the bores creates a good jet strength with a minimum of liquid. An additional nozzle cleans the body and the inlet nozzles of the container. The high-energy drops provide very effective impact up to 2.25 m (r). This ensures reliable cleaning of containers up to 4.5 m in diameter with just a single nozzle.

The TROLL BALL meets the hygiene and material requirements of the FDA. It can be used in the pharmaceutical, food, biotech, beverage and many other hygiene-conscious industries. The TROLL BALL is available in 180° and 360° upwards and downwards versions. The TROLL BALL is also available as a 2″ FanJet (fan nozzle) and 3″ version.

Threaded Connection

Troll Ball 2 standard devices are equipped with a 3/4″ cylindrical internal thread BSP (British Standard PIPE according to DIN ISO 228). The device is optionally available with a 3/4″ conical internal thread NPT (National Pipe Taper, American pipe thread for self-sealing connections).

Troll Ball 2″ FJ – Fan-Jet Nozzles

For applications where even liquid distribution is more important than high impact. The Troll Ball 2″ with fan-jet nozzles ensures an even and full coverage with cleaning liquid, but the cleaning effect is reduced due to the lack of jet bundling. This Troll Ball was developed for special applications. The device is also available with attached full-jet nozzles.

Troll Ball 2″ AV – Anti-Vibration/Full jet nozzles

The Troll Ball 2″ AV (anti-vibration) was developed for applications in which strong vibrations occur. The Troll Ball 2″ AV has a firmly screwed and secured ball instead of the cotter pin. The attached full jet nozzles increase the cleaning effect by an additional 15%. The AV variant is also available without full jet nozzles. Standard variants are also available without a cotter pin.

Troll Ball 2″ BSP Threaded Connection

| Connection | Spray pattern | Spray pattern | Product code | Materials | Certificates | Article number |

|---|---|---|---|---|---|---|

| Recommended standard devices with high storage probability are shown in blue. | ||||||

| 3/4″ IG-BSP | 360° Standard | Typ C | TB2AF-C360-BSP | 316L/C.PTFE | FDA, 3.1 | 4660-2102-113 |

| 3/4″ IG-BSP | 360° Standard | Typ C | TB2F-C360-BSP | 316L/PTFE | FDA, 3.1 | 4660-2105-112 |

| 3/4″ IG-BSP | 180° downwards | Typ G | TB2AF-G180-BSP | 316L/C.PTFE | FDA, 3.1 | 4660-2131-110 |

| 3/4″ IG-BSP | 180° downwards | Typ G | TB2F-G180-BSP | 316L/PTFE | FDA, 3.1 | 4660-2131-112 |

| 3/4″ IG-BSP | 180° upwards | Typ H | TB2AF-H180-BSP | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSP | 180° upwards | Typ H | TB2F-H180-BSP | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSP | 360° inverted | Typ D | TB2AF-D360-BSP | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSP | 360° inverted | Typ D | TB2F-D360-BSP | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSP | 360° FJ Standard | Typ B | TB2AF-B360-BSP | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSP | 360° FJ Standard | Typ B | TB2F-B360-BSP | 316L/PTFE | FDA, 3.1 | 4660-2133-113 |

| 3/4″ IG-BSP | 180° FJ downwards | Typ E | TB2AF-E180-BSP | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSP | 180° FJ downwards | Typ E | TB2F-E180-BSP | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSP | 360° FJ upwards | Typ F | TB2AF-F360-BSP | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSP | 360° FJ upwards | Typ F | TB2F-F360-BSP | 316L/PTFE | FDA, 3.1 | – |

Troll Ball 2″ NPT Threaded Connection

| Connection | Spray pattern | Spray pattern | Product code | Materials | Certificates | Article numbers |

|---|---|---|---|---|---|---|

| Recommended standard devices with high storage probability are shown in blue. | ||||||

| 3/4″ IG-NPT | 360° Standard | Typ C | TB2AF-C360-NPT | 316L/C.PTFE | FDA, 3.1 | 4660-2104-213 |

| 3/4″ IG-NPT | 360° Standard | Typ C | TB2F-C360-NPT | 316L/PTFE | FDA, 3.1 | 4660-2104-212 |

| 3/4″ IG-NPT | 180° downwards | Typ G | TB2AF-G180-NPT | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 180° upwards | Typ H | TB2AF-H180-NPT | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 180° upwards | Typ H | TB2F-H180-NPT | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 360° inverted | Typ D | TB2AF-D360-NPT | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 360° inverted | Typ D | TB2F-D360-NPT | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 360° FJ Standard | Typ B | TB2AF-B360-NPT | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 360° FJ Standard | Typ B | TB2F-B360-NPT | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 180° FJ downwards | Typ E | TB2AF-E180-NPT | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 180° FJ downwards | Typ E | TB2F-E180-NPT | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 180° FJ upwards | Typ F | TB2AF-F360-NPT | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 360° FJ upwards | Typ F | TB2F-F360-NPT | 316L/PTFE | FDA, 3.1 | – |

Troll Ball 2″ BSPT Threaded Connection

| Connection | Spray pattern | Spray pattern | Product code | Materials | Certificates | Article numbers |

|---|---|---|---|---|---|---|

| Recommended standard devices with high storage probability are shown in blue. | ||||||

| 3/4″ IG-BSPT | 360° Standard | Typ C | TB2AF-C360-BSPT | 316L/C.PTFE | FDA, 3.1 | 4660-2103-113 |

| 3/4″ IG-BSPT | 360° Standard | Typ C | TB2F-C360-BSPT | 316L/PTFE | FDA, 3.1 | 4660-2101-999 |

| 3/4″ IG-BSPT | 180° downwards | Typ G | TB2AF-G180-BSPT | 316L/C.PTFE | FDA, 3.1 | 4660-2131-113 |

| 3/4″ IG-BSPT | 180° downwards | Typ G | TB2F-G180-BSPT | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSPT | 180° upwards | Typ H | TB2AF-H180-BSPT | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSPT | 180° upwards | Typ H | TB2F-H180-BSPT | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSPT | 360° inverted | Typ D | TB2AF-D360-BSPT | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSPT | 360° inverted | Typ D | TB2F-D360-BSPT | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSPT | 360° FJ Standard | Typ B | TB2AF-B360-BSPT | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSPT | 360° FJ Standard | Typ B | TB2F-B360-BSPT | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSPT | 180° FJ downwards | Typ E | TB2AF-E180-BSPT | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSPT | 180° FJ downwards | Typ E | TB2F-E180-BSPT | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSPT | 360° FJ upwards | Typ F | TB2AF-F360-BSPT | 316L/C.PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSPT | 360° FJ upwards | Typ F | TB2F-F360-BSPT | 316L/PTFE | FDA, 3.1 | – |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 28.10.2022-71427321893-1888948-71042)