Torus 100 Rotating Nozzles

Plain bearing nozzle with fast rotation

effective cleaning

- no ball bearings

- fast rotation, effective cleaning

- FDA compliant & EX certified

- high speed, compact design

- only one moving part

- also available as TORUS 50/75 and made of plastic

- ultra-hygienic design

| Technical Data | Value |

|---|---|

| Max. cleaning diameter: | 4,8 Meter |

| Spray pattern: | 360° and 180° up-, downwards |

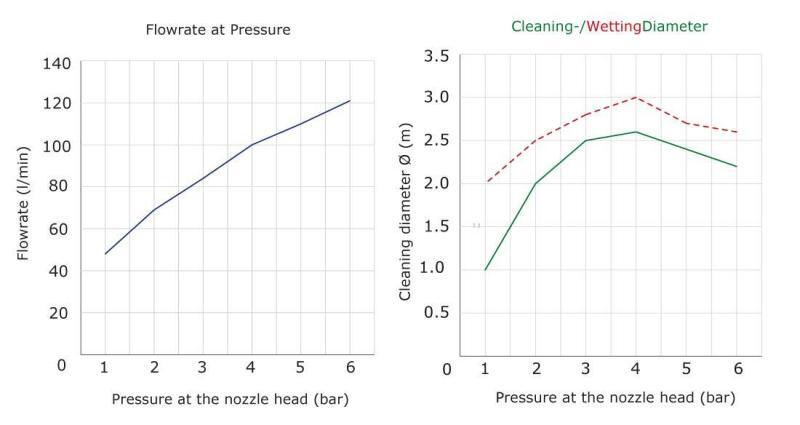

| Pressure range: | 1 – 6 bar |

| Flow rate: | 50 – 118 LPM (3,0 – 7,1 m³/h) |

| Insertion opening: | BSP/NPT min. Ø 60 mm, Splint min. Ø 85 mm |

| Mounting position: | arbitrary |

| Weight: | ca. 0,195 KG |

| Materials: | Stainless Steel 316L (1.4404), C.PTFE, PTFE, Hastelloy C22 |

| Pipe connection: | 3/4″ female thread BSP (NPT) |

| optional connections: | 1″ Split pin |

| Nozzle characteristics: | Ball with slots |

| Certificates: | 3.1, 2.2, ATEX, FDA, FDA Regulation (EC) No 1935/2004 |

| Max. operating temperature: | 65°C (149°F) |

| Max. ambient temperature: | 75°C (167°F), 30 Min. |

| Operating recommendation: | It is recommended to install a filter/strainer (500 μm) in the CIP supply line to the tank cleaner to protect it from particle clogging or damage. |

The fast-rotating Torus 100 rotary nozzles create a permanently uniform and instantaneously droplet-shaped liquid distribution. Intelligent fluid bearing design makes these rotary nozzles extremely durable compared to their ball bearing counterparts. An extensive range of 360°/180° spray patterns and many connection types are available.

Some of these products are highly resistant to operation with compressed air or steam (PEEK). Torus 1000 cleaning nozzles are ideally suited for the pharmaceutical and chemical industries and meet the highest hygiene requirements. Torus or Chemitorus Nozzles with C.PTFE rotor are also FDA compliant and EX free. Variants of Torus rotary nozzles are available in Hastelloy C22.

The TORUS 100 is suitable for low pressure applications with medium water volume. The ability to operate the TORUS 100 at even low pressures and flow rates starting at 50L gives it an advantage for many applications, installation is simple with a Split pin mounting. In operation, the cleaning fluid causes a rotor with slots to rotate rapidly, causing high-energy droplets to impact all around. The TORUS consists of only 2 parts and is ideal for impact cleaning and continuous cleaning with a strong cleaning effect. The TORUS cleans itself during operation. Due to the sliding bearing system of the TORUS, these nozzles can often be used for years with almost no wear. The TORUS also promises exceptional service life when used with compressed air or superheated steam sterilization and high temperatures (depending on the application).

The TORUS can replace static spray balls in tanks up to 4.8 meters and produces a full coverage distribution and good mechanical cleaning effect with a small amount of liquid. The TORUS is suitable for cleaning vessels and plant components in highly sensitive applications. It is compactly designed so that it can be installed inside pipelines. The TORUS is available in 3 different sizes.

The TORUS is made of FDA and/or ATEX certified materials. For the first time, ATEX and FDA certificates can be issued for these cleaning nozzles at the same time. The TORUS is available in 360° and 180° versions. The TORUS is also available as TORUS 50 and TORUS 75 with 3/8″ and 1/2″ connection or as CHEMITORUS 50/75.

Torus Variants

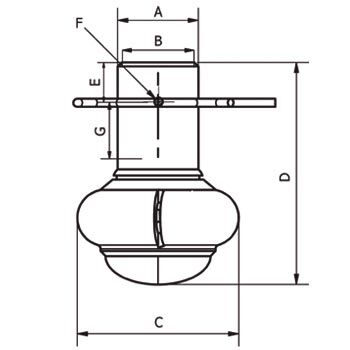

Torus Measurements and Connection Types

| Torus Measurements (mm) and Connection Types | |||||||

|---|---|---|---|---|---|---|---|

| Measurements (mm) | A | B* | C | D | E | F | G |

| B* (split pin version) corresponds to the inner diameter of the torus for mounting on a tube whose max. outer diameter must be taken into account. Further special adaptations possible. When purchasing a split pin version, the exact outside diameter of the existing tube must be known. A suitable split pin is supplied. BSP thread types are also available as NPT thread version. Split pin mounting up to 15% higher flow. | |||||||

| Torus 50 3/8″ IG-BSP | 20,00 | 3/8″ IG-BSP | 40,00 | 55,00 | – | – | – |

| Torus 50 1/2″ Split pin | 20,00 | 12,75 – 12,80 | 40,00 | 55,00 | 10,00 | 2,50 | 10,50 |

| Torus 50 DN10 Split pin | 20,00 | 13,05 – 13,10 | 40,00 | 55,00 | 10,00 | 2,50 | 10,50 |

| Torus 75 1/2″ IG-BSP | 24,00 | 1/2″ IG-BSP | 49,50 | 60,00 | – | – | – |

| Torus 75 3/4″ Split pin | 24,00 | 19,10 – 19,15 | 49,50 | 60,00 | 10,00 | 2,50 | 10,50 |

| Torus 75 DN15 Split pin | 24,00 | 19,05 – 19,10 | 49,50 | 60,00 | 10,00 | 2,50 | 10,50 |

| Torus 100 3/4″ IG-BSP | 29,00 | 3/4″ IG-BSP | 54,50 | 65,00 | 10,00 | 2,50 | 10,50 |

| Torus 100 1″ Split pin | 29,00 | 25,45 – 25,50 | 54,50 | 65,00 | 10,00 | 2,50 | 10,50 |

Torus 100 Threaded- and Split pin Connection

| Connection | Spraypattern | Pipe* | Product Code | Materials | Certificates | Article Numbers |

|---|---|---|---|---|---|---|

| *corresponds to the max. pipe outside diameter of the pipe on which the nozzle is to be installed (inch or mm). Recommended standard units with high stock probability are shown in blue. Torus are available with hand and electric polishing. Torus rotary nozzles can be manufactured from Hastelloy C22. It is possible to customize with PEEK or C.PEEK rotor, see PEEK Torus. Other customizations are possible. The chemitorus is completely made of plastic PTFE or C.PTFE. | ||||||

| 3/4″ IG-BSP | 360° | 3/4″ | T0100AF-360-BSP | 316L/C.PTFE | ATEX+FDA, 3.1 | 44660-1701-412 |

| 3/4″ IG-BSP | 360° | 3/4″ | T0100F-360-BSP | 316L/PTFE | FDA, 3.1 | 4660-1701-415 |

| 3/4″ IG-BSP | 180° downwards | 3/4″ | T0100AF-180A-BSP | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 3/4″ IG-BSP | 180° downwards | 3/4″ | T0100F-180A-BSP | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSP | 180° upwards | 3/4″ | T0100AF-180T-BSP | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 3/4″ IG-BSP | 180° upwards | 3/4″ | T0100F-180T-BSP | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 360° | 3/4″ | T0100AF-360-NPT | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 3/4″ IG-NPT | 360° | 3/4″ | T0100F-360-NPT | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 180° downwards | 3/4″ | T0100AF-180A-NPT | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 3/4″ IG-NPT | 180° downwards | 3/4″ | T0100F-180A-NPT | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 180° upwards | 3/4″ | T0100AF-180T-NPT | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 3/4″ IG-NPT | 180° upwards | 3/4″ | T0100F-180T-NPT | 316L/PTFE | FDA, 3.1 | – |

| 1″ Split pin | 360° | 25,40 | T0100F-360-PF | 316L/PTFE | FDA, 3.1 | 4660-1701-413 |

| 1″ Split pin | 360° | 25,40 | T0100AF-360-PF | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-1704-412 |

| 1″ Split pin | 180° downwards | 25,40 | T0100AF-180A-PF | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 1″ Split pin | 180° downwards | 25,40 | T0100F-180A-PF | 316L/PTFE | FDA, 3.1 | – |

| 1″ Split pin | 180° upwards | 25,40 | T0100AF-180T-PF | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 1″ Split pin | 180° upwards | 25,40 | T0100F-180T-PF | 316L/PTFE | FDA, 3.1 | – |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 14.12.2022-71427321893-1888948-71042)