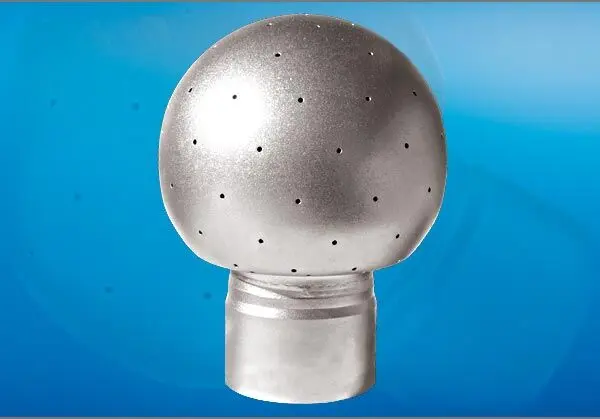

Sprayballs threaded connection

Extensive range with high quality workmanship

- 0.8 to 8.0 metre cleaning diameter

- 7 different spray pattern types available

- suitable for use in FDA & EX environments

- acid, alkali & temperature resistant

- 3 different ball sizes available

- inexpensive to purchase, reliable operation

- reasonable selection of high quality materials

| Technical Data | Value |

|---|---|

| Max. cleaning diameter: | 8 meters |

| Spraypattern: | 360°, 188°, 192°, 194°, 206°, 232°, 246° |

| Pressure Range: | 1,0 – 2,5 bar |

| Flowrate: | 40 – 1085 LPM (2,4 – 65,1 m³/h) |

| Insertion opening: | 30 mm bis 95 mm |

| Mounting position: | arbitrary |

| Materials: | Stainless Steel 316L (1.4404) |

| Standard Connection: | 1/4″, 1″, 2″ DIN ISO 228-1 IG |

| Surface: | matte |

| Nozzle Chracteristics: | Static Ball with Drillings |

| Certificates: | 3.1 DIN EN 10204, 2.2 |

| Operating recommendation | It is recommended to install a filter/screen (500 μm) in the CIP inlet line to the tank cleaner to protect it from clogging with particles or damage |

Thanks to high liquid volumes, fixed Sprayballs enable thorough cleaning even at low pressure. The cleaning effect is achieved by bombarding and rinsing the inner walls of the container. By adding suitable cleaning agents, the cleaning effect can be improved, thus shortening the cleaning time.

Two working methods are possible:

– permanent flushing

– pulse-pause operation

Pulse-pause operation reduces the amount of cleaning fluid for the same cleaning time compared to permanent blasting. This allows the cleaning medium used to unfold its effect.

Typ A/LA 360°,

standing and

lying Tanks

Typ B 192°-194°,

faced downwards

Typ G 206°-246°,

faced upwards

Typ L 188°,

faced upwards,

layingTanks

Pipe-types

| (DIN 11866 A-Series for Pipe outward dimensions) | DIN 11866 B-Series DIN EN ISO 1127 | DIN 11866 C-Series ASME-BPE 2005 | ||||||

|---|---|---|---|---|---|---|---|---|

| DR: Outer pipe dimensions s: Sprayball Wall thickness | ||||||||

| DN | DR (mm) | s (mm) | DN/OD | DR (mm) | s (mm) | DN | DR | s (mm) |

| 10 | 13 | 1,5 | 13,5 | 13,5 | 1,6 | 1/2″ | 12,7 | 1,65 |

| 15 | 19 | 1,5 | 17,2 | 17,2 | 1,6 | 3/4″ | 19,05 | 1,65 |

| 20 | 23 | 1,5 | 21,3 | 21,3 | 1,6 | |||

| 26,9 | 26,9 | 1,6 | ||||||

| 25 | 29 | 1,5 | 33,7 | 33,7 | 2,0 | 1″ | 25,4 | 1,65 |

| 40 | 41 | 1,5 | 42,4 | 42,4 | 2,0 | 1 1/2″ | 38,1 | 1,65 |

| 50 | 53 | 1,5 | 48,3 | 48,3 | 2,0 | 2″ | 50,8 | 1,65 |

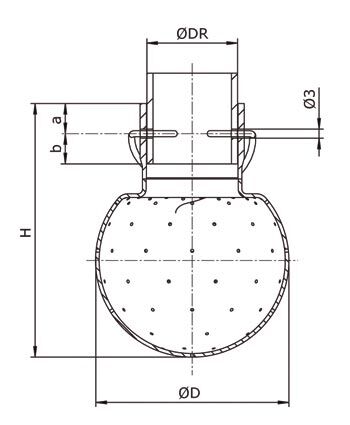

Drilling dimensions

| Typ 05 | Typ 1 | Typ 2 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 316L (1.4404) | 316L (1.4435) | Alloy 59 (2.4605) | 316L (1.4404) | 316L (1.4435) | Alloy 59 (2.4605) | 316L (1.4404) | ||||||

| Ø DR | 12 mm | 13 mm | 1/2″ OD mm | 13,5 mm | 1/2″ OD mm | 29 mm | 1″ OD mm | 29 mm | 33,7 mm | 33,7 mm | 53 mm | 2″ OD mm |

| Ø D | 28 | 28 | 28 | 28 | 28 | 64 | 64 | 64 | 64 | 64 | 93 | 93 |

| H | 46,6 | 46,6 | 46,6 | 46,6 | 46,6 | 84 | 84 | 84 | 84 | 84 | 113,5 | 113,5 |

| b+a | 18 | 18 | 16 | 18 | 18 | 20 | 20 | 20 | 16,5 | 16,5 | 30 | 30 |

| a | 10 | 10 | 8 | 10 | 10 | 10 | 10 | 10 | 6 | 6 | 10 | 10 |

| b | 8 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10,5 | 10,5 | 20 | 20 |

| Drilling from Underside Pipe | ||||||||||||

| b-0,2 | 7,8 | 7,8 | 7,8 | 7,8 | 7,8 | 9,8 | 9,8 | 9,8 | 10,3 | 10,3 | 19,8 | 19,8 |

| Type | Spray angle | Cleaning Range Ø m | 1,0 bar m³/h | 1,5 bar m³/h | 1,8 bar m³/h | 2,0 bar m³/h | 2,2 bar m³/h | 2,5 bar m³/h | D mm | H mm | Pipe DIN ISO 228-1 | Order-Code |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow rate with electropolished spray balls approx. 15 – 20% higher than indicated in the table. Recommended operating pressure 1.0 to 2.5 bar at the inlet of the spray ball. The guideline value for cleaning fluid per metre of tank circumference is 30 to 50 l/min. | ||||||||||||

| A05 | 360° | 1,0-2,0 | 4,7 | 5,8 | 6,3 | 6,6 | 7,0 | 7,4 | 28 | 25 | G1/4″ | G-253-106.01 |

| A05-1,0 | 360° | 0,8-1,5 | 2,4 | 2,9 | 3,2 | 3,4 | 3,6 | 3,8 | 28 | 25 | G1/4″ | G-253-106.26 |

| A1-1,0 | 360° | 1,5-2,5 | 2,5 | 3,1 | 3,4 | 3,5 | 3,7 | 4,0 | 64 | 84 | G1″ | G-253-106.34 |

| A1-1,5 | 360° | 1,8-3,0 | 6,5 | 8,0 | 8,7 | 9,2 | 9,6 | 10,3 | 64 | 84 | G1″ | G-253-106.35 |

| A1 | 360° | 2,0-3,0 | 9,4 | 11,5< /td> | 12,6 | 13,3 | 13,9 | 14,9 | 64 | 84 | G1″ | G-253-106.10 |

| A1-1 | 360° | 2,5-3,5 | 12,3 | 15,1 | 16,5 | 17,4 | 18,2 | 19,4 | 64 | 84 | G1″ | G-253-106.11 |

| A1-2 | 360° | 3,0-4,0 | 14,8 | 18,1 | 19,9 | 20,9 | 22,0 | 23,4 | 64 | 84 | G1″ | G-253-106.12 |

| A2 | 360° | 3,5-5,0 | 20,9 | 25,6 | 28,0 | 29,6 | 31,0 | 33,0 | 93 | 113,5 | G2″ | G-253-106.36 |

| A2-1 | 360° | 4,0-6,0 | 27,3 | 33,4 | 36,6 | 38,6 | 40,5 | 43,2 | 93 | 113,5 | G2″ | G-253-106.37 |

| A2-2 | 360° | 5,0-7,0 | 34,6 | 42,4 | 46,4 | 48,9 | 51,3 | 54,7 | 93 | 113,5 | G2″ | G-253-106.38 |

| A2-3 | 360° | 6,0-8,0 | 39,9 | 48,9 | 53,5 | 56,4 | 59,2 | 63,1 | 93 | 113,5 | G2″ | G-253-106.33 |

| B05 | 192° | 1,0-2,0 | 2,5 | 3,1 | 3,4 | 3,5 | 3,7 | 4,0 | 28 | 25 | G1/4″ | G-253-106.02 |

| B1 | 192° | 2,0-3,0 | 9,0 | 11,0 | 12,1 | 12,7 | 13,3 | 14,2 | 64 | 84 | G1″ | G-253-106.13 |

| B2 | 194° | 3,5-5,0 | 21,4 | 26,2 | 28,7 | 30,3 | 31,7 | 33,8 | 93 | 113,5 | G2″ | G-253-106.39 |

| B2-3 | 194° | 6,0-8,0 | 41,2 | 50,5 | 55,3 | 58,3 | 61,1 | 65,1 | 93 | 113,5 | G2″ | G-253-106.42 |

| G05 | 232° | 1,0-2,0 | 4,2 | 5,1 | 5,6 | 5,9 | 6,2 | 6,6 | 28 | 25 | G1/4″ | G-253-106.22 |

| G1 | 206° | 2,0-3,0 | 8,7 | 10,7 | 11,7 | 12,3 | 12,9 | 13,8 | 64 | 84 | G1″ | G-253-106.19 |

| G1-1 | 206° | 2,5-3,5 | 10,7 | 13,1 | 14,4 | 15,1 | 15,9 | 16,9 | 64 | 84 | G1″ | G-253-106.20 |

| G1-2 | 206° | 3,0-4,0 | 14,0 | 17,1 | 18,8 | 19,8 | 20,8 | 22,1 | 64 | 84 | G1″ | G-253-106.21 |

| G2 | 246° | 3,5 -5,0 | 19,1 | 23,4 | 25,6 | 27,0 | 28,3 | 30,2 | 93 | 113,5 | G2″ | G-253-106.47 |

| G2-1 | 246° | 4,0-6,0 | 25,8 | 31,6 | 34,6 | 36,5 | 38,3 | 40,8 | 93 | 113,5 | G2″ | G-253-106.48 |

| G2-2 | 246° | 5,0-7,0 | 33,7 | 41,3 | 45,2 | 47,7 | 50,0 | 53,3 | 93 | 113,5 | G2″ | G-253-106.49 |

| G2-3 | 246° | 6,0-8,0 | 40,0 | 49,0 | 53,7 | 56,6 | 599,3 | 53,3 | 93 | 113,5 | G2″ | G-253-106.50 |

| L1 | 188° | 2,5-3,0 | 8,1 | 9,9 | 10,9 | 11,5 | 12,0 | 12,8 | 64 | 84 | G1″ | G-253-106.73 |

| LA1-1,5 | 360° | 2,5-3,0 | 10,5 | 12,9 | 14,1 | 14,8 | 15,6 | 16,6 | 64 | 84 | G1″ | G-253-106.77 |

Installation Lance

| Materials: | Stainless Steel 1.4404 (316L), EPDM, FKM |

| Certificate: | 3.1, 2.2 |

| Device Connection: | see Table |

| Tank connection: | Flange on demand |

| Sensor: | without SMW 100 |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 31.10.2023-71427321893-1888948-71042)