Caskwasher Rotating nozzles

Protected Turbodisc 25 barrel cleaner

- no ball bearings

- fast rotation and low liquid volumes

- FDA compliant & EX certified

- maintenance free for many years

- very few individual components

- protected against damage

- uniform cleaning pattern

| Technical Data | Value |

|---|---|

| Max cleaning parameter: | 1,5 meter |

| Spray pattern: | 180° |

| Cleaning area: | 360° |

| Pressure range: | 2-bar |

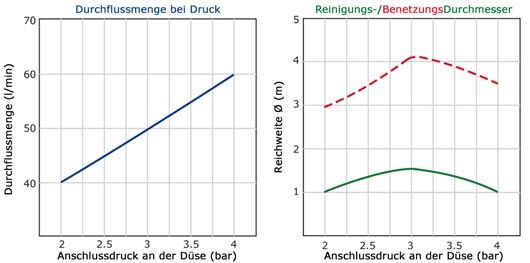

| Flow rate: | 40 – 60 LPM (2,4 – 3,6 m³/h) |

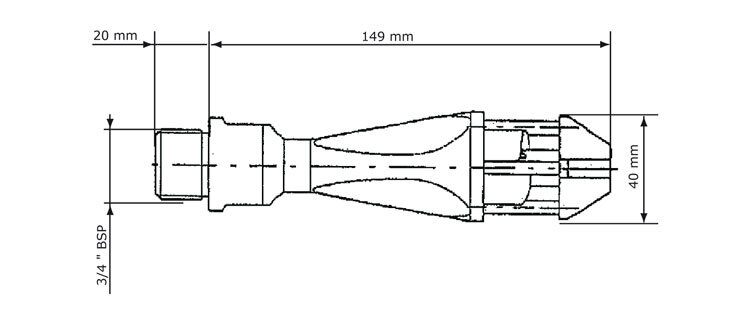

| Insertion opening: | min. Ø 45 mm |

| Mounting position: | arbitrary |

| Weight: | on request |

| Materials: | Stainless Steel 316L (1.4404), C.PTFE, PTFE, PEEK |

| Standard Pipe connection: | 3/4″ external thread |

| Optional Pipe connections: | on request |

| Nozzle characteristics: | Turbodisc 25 180° |

| Certificates: | 3.1, 2.2, ATEX, FDA, FDA Regulation (EC) No 1935/2004 |

| Max. operating temperature: | 95°C (2003°F) |

| Max. ambient temperature: | 140°C (284°F), 30 Min. |

| Operation recommendation: | It is recommended to install a filter/screen (500 μm) in the CIP inlet line to the tank cleaner to protect it from clogging with particles or damage. |

The TURBODISC CASKWASHER is a compact and powerful cleaning device specially designed for various types of barrels and containers in the wine industry. In operation, the CASKWASHER is located underneath the container with the cleaner entering the container or the container being exposed to the cleaner. The rotation of the TURBODISC distributes the cleaning medium evenly throughout the container with effective mechanical energy.

The CASKWASHER is driven only by the cleaning medium creating an excellent and uniformly continuous cleaning by impacting drops on the container wall.

The cleaning liquid is directed in the caskwasher onto a disc centrifuge, which rotates frictionlessly at high speed on a bearing of cleaning liquid. The operating action is instantaneous, high impact and full coverage.

A cage eliminates damage to the spray head, making the TURBODISC CASKWASHER suitable for automated cleaning or launching.

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 22.12.2022-71427321893-1888948-71042)