Cyclone Orbital Cleaner

Radial und axial rotating target cleaner without nozzles

- Hygienic and compact design

- Pressure range 4 – 10 bar

- Cleaning diameter up to 14 m

- Flow rate between 42 – 103 lpm

- Insertion opening 80 mm

- FDA compliant & EX certified

- Driven by the cleaning medium

- Ball bearing free, Self-cleaning

- Monitoring with sensor SMW 100 or Veri-Clean

Cyclone orbital tank washer – small, strong and compact

| Technical Data | Value |

|---|---|

| Max. cleaning diameter: | 14 meters |

| Spray pattern: | 360° orbital |

| Pressure range: | 4 – 10 bar |

| Flow rate: | 42 – 103 LPM (2,5 – 6,2 m³/h) |

| Insertion opening: | min. Ø 80 mm |

| Preferred mounting position: | beliebig, vertikal bevorzugt |

| Weight: | ca. 2,0 KG |

| Materials: | Stainless Steel 316L (1.4404), C.PTFE, PTFE, C.PEEK |

| Pipe connection: | 3/4” BSP (NPT) female |

| Optional Pipe Connections: | 1” OD Splint (25.4 x 1.6mm) |

| Nozzle characteristics: | 4 x 3,0 mm nozzles, 4 x 4,0 mm nozzles |

| Certificates: | 3.1, 2.2, ATEX, FDA, Regulation (EC) No 1935/2004 |

| Max. operating temperature: | 95°C (203°F) |

| Max. ambient temperature: | 140°C (284°F), 30 Min. |

| Betriebsempfehlung: | It is recommended to install a filter/strainer (500 μm) in the CIP supply line to the tank cleaner to protect it from particle clogging or damage. |

The Cyclone is an extremely small jet cleaner with an orbital 360° spray pattern. An installation opening of only 80 mm is required to install a Cyclone. The cyclone is driven by the cleaning medium at a pressure of 4 to 10 bar. A radial and axial rotation of the nozzle head is generated by turbine drives. This creates liquid jets aligned through four nozzles with a strong impact effect up to a diameter of 14 meters. With liquid jets running around, a complete spray pattern with full coverage is achieved within 3.5 to 6 minutes.

Thanks to optimal flow control, a smooth-running mechanism without ball bearings and a hygienic sealing concept, the energy used in the device unfolds in a strong cleaning effect. The orbital cleaning behavior enables the best possible use of the cleaning liquid or chemical additives. For use in hygiene-sensitive areas, the device keeps itself permanently clean with a self-cleaning nozzle and empties itself automatically after use in vertical operation.

The use of the device is always resource-saving and takes place with the lowest wear and tear and maintenance costs. The Cyclone meets the highest hygiene and safety standards and can be used in EX zones and FDA applications at the same time. During a long service life, this device will always prove to be a reliable partner for your cleaning tasks. Optionally, the cleaning process of a cyclone can be permanently and non-invasively monitored by SMW 100 or Vericlean. The Cyclone is one of the latest and most effective developments in the cleaning technology market.

Cyclone orbital cleaners are available in many connection variants. The Cyclone is very compact and can be installed in any position in vessels or equipment using a 3/4” threaded connection or a choice of cotter pin or clamp mounting. It can also be used on a lance or hanging from a hose. Common uses for this product are tanks and vessels in the brewing, beverage, dairy, food, pharmaceutical, chemical and transportation industries.

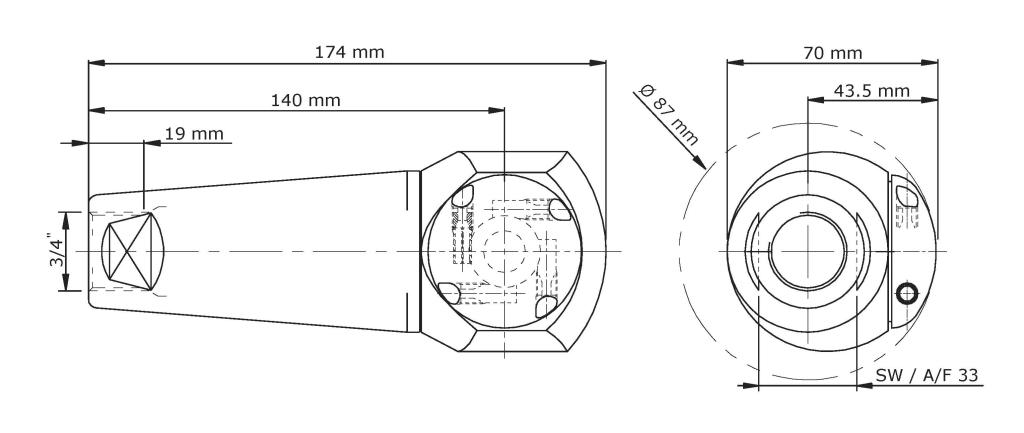

Threaded connection

Cyclone standard devices are equipped with a 3/4″ cylindrical internal thread BSP (British Standard PIPE according to DIN ISO 228). The device is optionally available with a 3/4″ conical internal thread NPT (National Pipe Taper, American pipe thread for self-sealing connections).

Cyclone with 3/4″ Thread connection

| Connection | Nozzles | Pipe* | Product Code | Materials | Certificates | Article number |

|---|---|---|---|---|---|---|

| *corresponds to the maximum pipe OD of the pipe on which the machine is to be installed (inches or mm). | ||||||

| 3/4″ IG-BSP | 4 x 3,0 mm | 3/4″ | Cyclone-AF4x3S-BSP | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 3/4″ IG-BSP | 4 x 3,0 mm | 3/4″ | Cyclone-F4x3S-BSP | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 4 x 3,0 mm | 3/4″ | Cyclone-AF4x3S-NPT | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 3/4″ IG-NPT | 4 x 3,0 mm | 3/4″ | Cyclone-F4x3S-NPT | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-BSP | 4 x 4,0 mm | 3/4″ | Cyclone-AF4x4S-BSP | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 3/4″ IG-BSP | 4 x 4,0 mm | 3/4″ | Cyclone-F4x4S-BSP | 316L/PTFE | FDA, 3.1 | – |

| 3/4″ IG-NPT | 4 x 4,0 mm | 3/4″ | Cyclone-AF4x4S-NPT | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 3/4″ IG-NPT | 4 x 4,0 mm | 3/4″ | Cyclone-F4x4S-NPT | 316L/PTFE | FDA, 3.1 | – |

Cyclone mit 1″ Splintanschluss

| Connection | Nozzles | Pipe* | Product Code | Materials | Certificates | Article number |

|---|---|---|---|---|---|---|

| *corresponds to the maximum pipe OD of the pipe on which the machine is to be installed (inches or mm). | ||||||

| 1″ Splint | 4 x 3,0 mm | 3/4″ | Cyclone-AF4x3S-100PF | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 1″ Splint | 4 x 3,0 mm | 3/4″ | Cyclone-F4x3S-100PF | 316L/PTFE | FDA, 3.1 | – |

| 1″ Splint | 4 x 4,0 mm | 3/4″ | Cyclone-AF4x4S-100PF | 316L/C.PTFE | ATEX+FDA, 3.1 | – |

| 1″ Splint | 4 x 4,0 mm | 3/4″ | Cyclone-F4x4S-100PF | 316L/PTFE | FDA, 3.1 | – |

Tank Cleaning trolley

| Materials: | Stainless Steel 316L (1.4404), PP (PTFE) |

| Certificates: | FDA, 3.1, 2.2 |

| Device connection: | 3/4″ AG-BSP |

| Supply Line: | DN50 threaded socket DIN 11851 |

Welding adapter

| Materials: | Stainless Steel 1.4404 (316L) |

| Certificates: | 3.1, 2.2 |

| Device connection: | 3/4″ AG-BSP |

| Supply Line: | Welding end |

SMW 100 liquid sensor

| Materials: | 1.4305, PEEK |

| Connection Type: | Welding sleeve |

| Function: | Sensor surge is displayed every 20 seconds |

Installation lance

| Materials: | Stainless Steel 1.4404 (316L), EPDM, FKM |

| Certificates: | 3.1, 2.2 |

| Device Connection: | 3/4″ AG-BSP (1″ Splint) |

| Tank connection: | Flange if needed |

| Sensor: | with/without SMW 100 |

Vericlean Rotation counter

| Materials: | Edelstahl 316L (1.4404), PTFE |

| Certificates: | 3.1, 2.2 |

| Device connection: | 3/4″ AG-BSP |

| Tank connectioin: | Flange if needed |

| Sensor type: | IFM MFT200 |

| Surveillance: | The rotation speed of the cleaning machine is permanently displayed |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 09.10.2022-71427321893-1888948-71042)