High-Pressure lance HL-A with air-pressure-motor

Effective high-pressure IBC and container cleaning with air motor

- 360° and 270° spray head possible

- strong jet power with low consumption values

- working pressure 70-250 bar

- Operation with commercially available high pressure cleaners

- compact dimensions, easy to handle

- hygienic and low-wear application

| Technical Data | Value |

|---|---|

| Max cleaning parameter: | 2 meter |

| Spray pattern: | 360° / 270° orbital |

| Number of Nozzles: | 2,3 or 4 Nozzles |

| Nozzle Types: | 0° spot jet, optional 5/15° flat jet nozzle |

| Pressure range: | 70 – 250 bar |

| Flow rate: | 30 – 200 LPM (1,8 – 12 m³/h) |

| Max. operating temperature: | 150° Celsius |

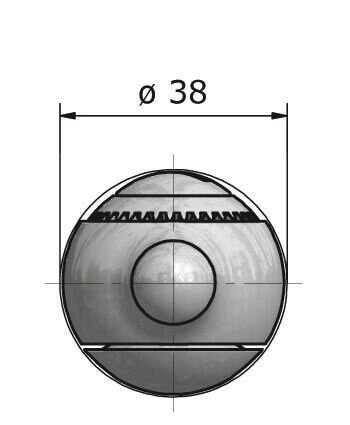

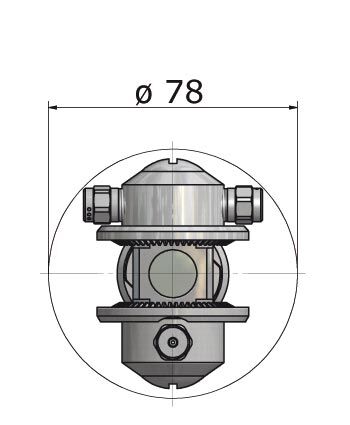

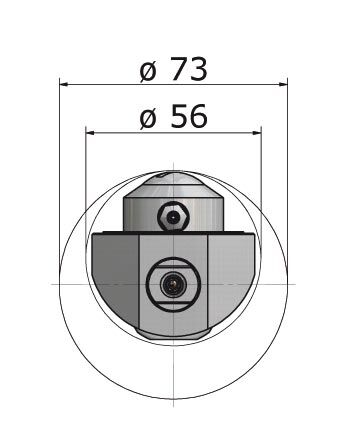

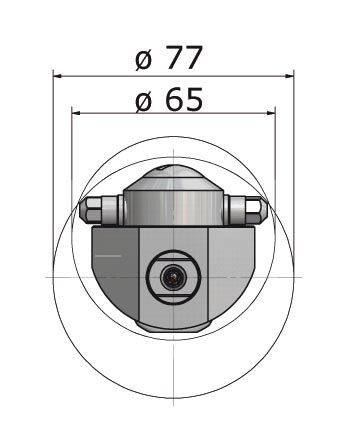

| Insertion opening: | 38 – 78 mm, depending on nozzle type |

| Rotating Speed: | 10 – 20 t/min, adjustable |

| Shaft Lenght: | 200 – 4000 mm, Special lengths on request |

| Mounting position: | arbitrary |

| Weight: | 5 – 20 KG, depending on shaft length |

| Materials: | Stainless Steel 316L 304, 301, Viton, (EPDM/PTFE) more on request |

| Standard Pipe connection: | 3/8″ AG, Optional M22x1,5 AG |

| Nozzle thread: | 1/8″, M6, M4, depending on device |

| Certificates: | 2.2, CE, ATEX, FDA on request |

| Ex version: | possible only with HL-A and HL-H |

High-pressure cleaners operate with a three-dimensionally rotating spray head, driven by an electric, compressed air or water-hydraulic motor. An orbital motion of both rotational axes forms a 360-degree spray pattern.

An extensive selection of spray head types allows these units to be used in a wide variety of applications.

The use of these devices is simple, these pressure washers can be connected to almost any standard high-pressure unit and stationary high-pressure pump. The shaft length of a device can be designed between 140 mm and 4000 mm, depending on the needs.

Compressed air and water-hydraulically driven variants are suitable for use in EX zones, and many of the unit types offered are FDA-compliant.

An extensive range of accessories is offered for handling and installation.

| HL-A-R55 | HL-A-R40 | HL-A-R32 | HL-A-R37 | HL-A-RD | HL-A-RD70 | HL-A-RC | HL-A-RW | |

|---|---|---|---|---|---|---|---|---|

| Materials | 316L | 316L | 316L | 316L | 316L | 316L | 316L | 316L |

| Nozzle amount | 2/3/4 | 2/3/4 | 2 | 2 | 4 | 4 | 2 | 2 |

| Insertion opening min. | 54 | 50 | 38 | 38 | 78 | 78 | 56 | 68 |

| Nozzle thread | 1/8″ | M6 | M4 | M4 | 1/8″ | 1/8″ | 1/8″ | 1/8″ |

| Amount max. LPM | 50 | 50 | 30 | 30 | 80 | 200 | 50 | 50 |

| Temperature max. | 150°C | 150°C | 150°C | 150°C | 150°C | 150°C | 150°C | 150°C |

| Spraypattern | 360° | 360° | 360° | 360° | 360° | 360° | 360° | 270° |

| Rotation t/min | 10 – 20 t/min, adjustable | |||||||

| Noise Emission | 77 dBA, measured at the motor | |||||||

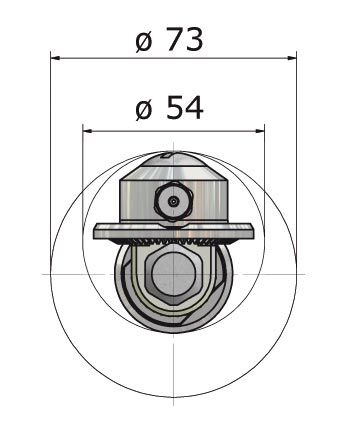

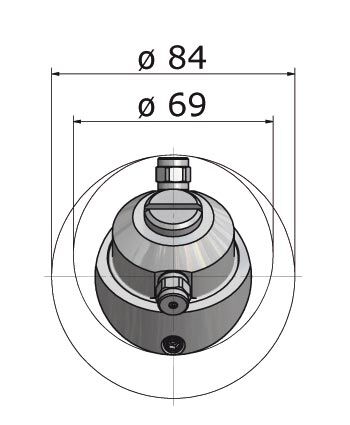

Sprayhead R55

max. 250 bar, max. 50 liters/minutemax. shaft length: 4000 mm

Minimum dimension of the installation opening for linear insertion of the spray heads.

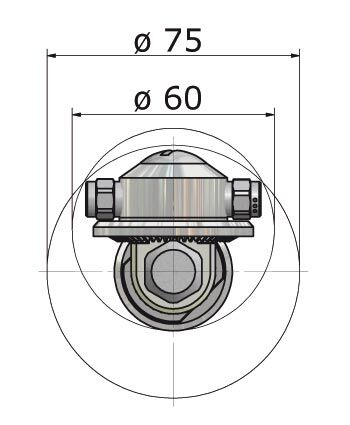

Sprayhead R40

max. shaft length: 4000 mm

Minimum dimension of the installation opening for linear insertion of the spray heads.

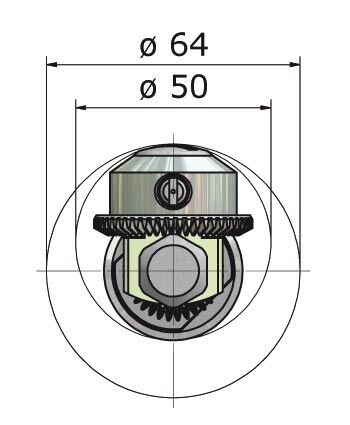

Sprayhead R32

max. shaft length: 4000 mm

Minimum dimension of the installation opening for linear insertion of the spray heads.

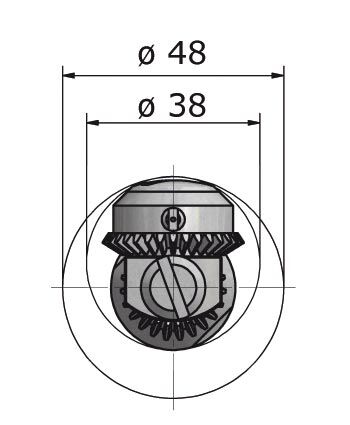

Sprayhead R37

max. shaft length: 4000 mm

Minimum dimension of the installation opening for linear insertion of the spray heads.

Double-Sprayhead RD

max. shaft length: 4000 mm

Minimum dimension of the installation opening for linear insertion of the spray heads.

Double-Sprayhead RD70

max. shaft length: 4000 mm

Minimum dimension of the installation opening for linear insertion of the spray heads.

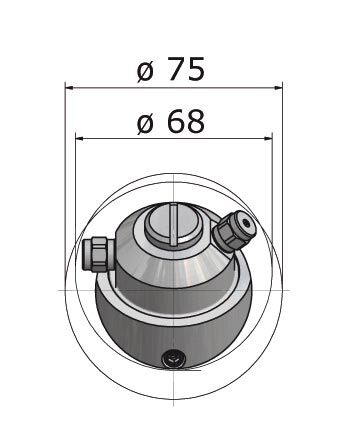

Sealed Sprayhead RC

max. 250 bar, max. 50 liters/minutemax. shaft length: 4000 mm

Minimum dimension of the installation opening for linear insertion of the spray heads.

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All data are without guarantee. (Stand: 26.12.2022-71427321893-1888948-71042)