Turbo SSB 75 Rotating Nozzle

Plain bearing nozzle with slow rotation

- 360° low pressure plain bearing nozzle

- slow rotation and small amounts of liquid

- FDA compliant & EX certified

- acid, alkali and temperature resistant

- compact dimensions

- self-cleaning, hygienic, low-wear

- high operational reliability

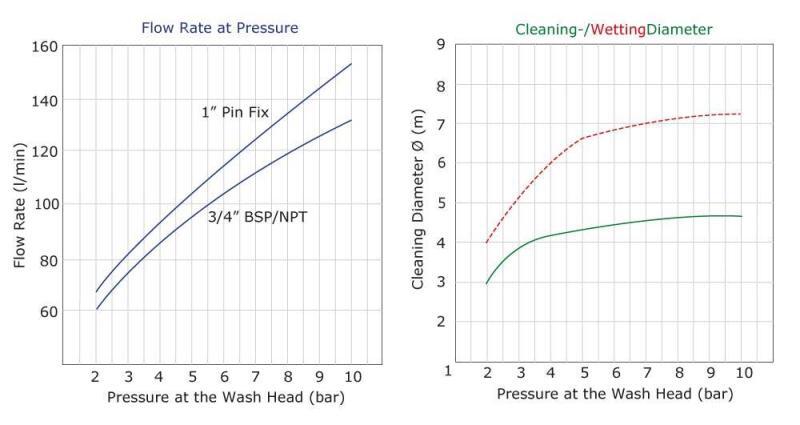

| Technical Data | Value |

|---|---|

| Max. cleaning diameter: | 4,7 meters |

| Spray pattern: | 360° |

| Pressure range: | 2 – 10 bar |

| Flow rate: | 60 – 153 LPM (3,6 – 9,2 m³/h) |

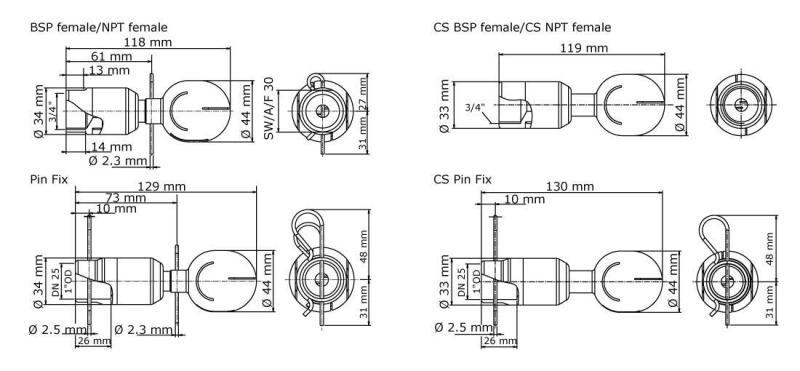

| Insertion opening: | SSB 75 BSP/NPT min. Ø 60 mm, Splint min. Ø 85 mmSSB 75 CS BSP/NPT min. Ø 45 mm, Splint min. Ø 85 mm |

| Mounting position: | arbitrary, preferrably vertical downwards |

| Weight: | approx. 0,37 KG |

| Materials: | Stainless Steel 316L (1.4404), C.PTFE, PTFE |

| Pipe connection: | 3/4″ Internal Thread BSP (NPT) |

| Optional Pipe Connections: | 1″ Splint, DN25 Splint |

| Nozzle characteristics: | Ball with slots |

| Certificates: | 3.1, 2.2, ATEX, FDA Regulation (EC) No 1935/2004 |

| Max. operating temperature: | 95°C (203°F) |

| Max. ambient temperature: | 140°C (284°F), 30 Min. |

| Operating recommendation: | It is recommended to install a filter/strainer (500 μm) in the CIP supply line to the tank cleaner to protect it from particle clogging or damage. |

The Turbo SSB 75 is a slowly rotating rotary nozzle. During operation, liquid flowing through it sets the ball head into a steady braked rotation. In the process, flat jets of liquid with a long range emerge through slots. The slow rotation of the nozzle favours an effective bundled liquid impact with a high impact effect. This achieves a cleaning effect of up to 4.7 metres in diameter. The Turbo SSB is equipped with an extremely low-wear slide bearing system that is permanently flushed with liquid, thus achieving extremely long service lives. Even brief exposure to steam or compressed air does not cause any damage. After years of permanent use within a wide variety of industrial applications, no operational failures caused by wear have been detected. The nozzle can be easily cleaned of solids by means of a removable ball head.

The Turbo SSB meets the highest hygiene standards as well as FDA requirements and is suitable for use in potentially explosive atmospheres. The Turbo SSB 75 is available as a CS version without a split pin on the ball head or completely without a split pin. Turbo SSB are available in 3 sizes and many connection types. Common applications for Turbo SSB 75 rotary nozzles are found in the dairy, food, beverage, pharmaceutical and chemical industries for cleaning production, process or transport containers.

We strongly recommend the installation of a 500 micron filter/strainer in the CIP supply line close to the tankwasher

to protect it against particulate blocking or damage.

Threaded Connection

Turbo SSB 75 standard devices are equipped with a 3/4″ cylindrical internal thread BSP (British Standard PIPE according to DIN ISO 228). The device is optionally available with a 3/4″ conical internal thread NPT (National Pipe Taper, American pipe thread for self-sealing connections).

Turbo SSB 75 Threaded and Split pin connection

| Connection | Spray Pattern | Pipe* | Product code | Materials | Certificates | Article numbers |

|---|---|---|---|---|---|---|

| *corresponds to the maximum pipe OD of the pipe on which the nozzle is to be installed (inches or mm). Split pin versions have approx. 15% higher flow-rates. Recommended standard devices with high storage probability are colored in blue. | ||||||

| 3/4″ IG-BSP | 360° | 3/4″ | TSSB75AF-360-BSP | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-2337-113 |

| 3/4″ IG-BSP | 360° | 3/4″ | TSSB75F-360-BSP | 316L/PTFE | FDA, 3.1 | 4660-2336-112 |

| 3/4″ IG-NPT | 360° | 3/4″ | TSSB75AF-360-NPT | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-2341-213 |

| 3/4″ IG-NPT | 360° | 3/4″ | TSSB75F-360-NPT | 316L/PTFE | FDA, 3.1 | 4660-2346-212 |

| 1″ Split pin | 360° | 25,40″ | TSSB75AF-360-PF | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-2342-413 |

| 1″ Split pin | 360° | 25,40″ | TSSB75F-360-PF | 316L/PTFE | FDA, 3.1 | 4660-2347-412 |

| DN25 Split pin | 360° | 29,12 | TSSB75AF-360-DN25 | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-2558-413 |

| DN25 Split pin | 360° | 29,12 | TSSB75F-360-DN25 | 316L/PTFE | FDA, 3.1 | 4660-2558-414 |

Turbo SSB 75 CS Threaded and Split pin connection

| Connection | Spray Pattern | Pipe* | Product code | Materials | Certificates | Article numbers |

|---|---|---|---|---|---|---|

| *corresponds to the maximum pipe OD of the pipe on which the nozzle is to be installed (inches or mm). Split pin versions have approx. 15% higher flow-rates. Recommended standard devices with high storage probability are colored in blue. | ||||||

| 3/4″ IG-BSP | 360° | 3/4″ | TSSB75AF-CS360-BSP | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-2558-421 |

| 3/4″ IG-BSP | 360° | 3/4″ | TSSB75F-CS360-BSP | 316L/PTFE | FDA, 3.1 | 4660-2558-418 |

| 3/4″ IG-NPT | 360° | 3/4″ | TSSB75AF-CS360-NPT | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-2558-422 |

| 3/4″ IG-NPT | 360° | 3/4″ | TSSB75F-CS360-NPT | 316L/PTFE | FDA, 3.1 | 4660-2558-424 |

| 1″ Split pin | 360° | 25,40 | TSSB75AF-CS360-PF | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-2558-423 |

| 1″ Split pin | 360° | 25,40 | TSSB75F-CS360-PF | 316L/PTFE | FDA, 3.1 | 4660-2558-425 |

| DN25 Split pin | 360° | 29,12 | TSSB75AF-CS360-DN25 | 316L/C.PTFE | ATEX+FDA, 3.1 | 4660-2558-420 |

| DN25 Split pin | 360° | 29,12 | TSSB75F-CS360-DN25 | 316L/PTFE | FDA, 3.1 | 4660-2558-419 |

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 27.10.2022-71427321893-1888948-71042)