SMW 100 Monitoring sensor

Sensor for monitoring liquid surges in tank interiors

- FDA / EHEDG compliant

- Monitoring of orbital cleaners and rotary nozzles

- high process reliability

- highest hygiene standard

- extensive evaluation options

- acid, alkali and temperature resistant

- Wetted components made of PEEK

- easy retrofitting for existing cleaners

| Operating Pressure: | max. 10 bar |

| Materials: | 1.4305, PEEK |

| Supply voltage: | 18…32 VDC PNP |

| On power requirement: | < 20 mA |

| Output signal active: | max. 50 mA PNP |

| Switch-on delay: | ≤ 0,3 s |

| Response time: | < 75 ms |

| Degree of protection: | IP 65/67 |

| Rated temperature: | 25°C |

| Ambient temperature: | -10…+70°C |

| Operating temperature: | 0…100°C |

| CIP-/SIP-Cleaning temperature: | 0…150°C, max. 30Min. |

| Purpose: | For use in water and water-based cleaning fluids |

| Kinematic viscosity: | 1,004×10ˉ6 m2/s |

| Conductance: | 0,005 S/m |

The SMW 100 is a sensor for monitoring rotating cleaning equipment. During operation, the liquid distribution of a cleaning nozzle is continuously checked. A permanent status signal is sent to a control unit.

The patented SMW 100 sensor is unique in its functionality. The sensor works according to a capacitive measuring principle and is therefore able to display malfunctions during the cleaning process within a very short time. If no jet of liquid runs past the sensor within a period of 20 seconds, for example, or if there is no surge of liquid, the sensor emits an error signal. Optionally, the system can be configured with extended electronics to record each individual jet of liquid. For example, the course of each individual nozzle of an orbital cleaner can be recorded.

The SMW 100 is suitable for monitoring the latest generation of orbital cleaners. These include OC200, Cyclone, Twister, Typhoon, Tempest, Tornado 2, Tornado 4, Torrent and TMC. It is also possible to monitor conventional jet cleaners.

The intelligent measuring principle of the SMW 100 also enables the monitoring of slowly rotating spray balls. Spray balls from the Turbo SSB series can also be monitored with the SMW 100.

The SMW 100 is FDA and EHEDG compliant and is mounted on a flange or in the tank wall in an extremely hygienic manner. By using an SMW 100 in a production plant, a high degree of process reliability can be achieved.

We offer an innovative range of solutions. Alternatively, consider our product Vericlean for monitoring our orbital cleaners through to monitoring many components involved in the cleaning process.

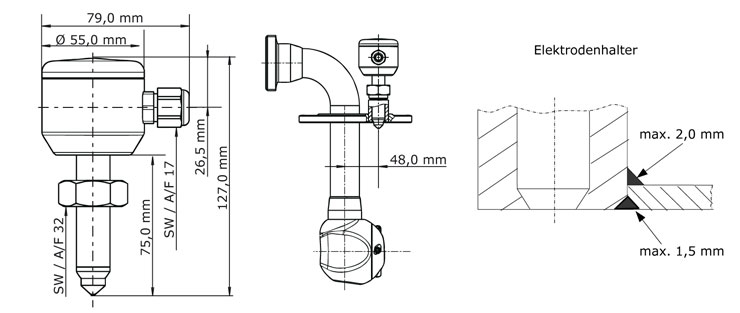

An installation lance is available as an accessory. The sensor holder is already integrated. The installation lance is equipped with an orbital cleaner, a jet cleaner or a slowly turning rotary nozzle.

A weld-on adapter is optionally available for the SMW 100 for easy installation or retrofitting in existing systems.

The data, technical data and information presented do not release the user from the obligation to check the suitability of the products supplied for the intended application. All information is without guarantee. (Status of: 24.10.2022-71427321893-1888948-71042)